Fix thermal-pressure motor lock: Difference between revisions

Robertbaxter (talk | contribs) No edit summary |

Robertbaxter (talk | contribs) No edit summary |

||

| Line 6: | Line 6: | ||

|tools={{Tutorial/tool | |tools={{Tutorial/tool | ||

|tool_name=Phillips #2 screwdriver | |tool_name=Phillips #2 screwdriver | ||

}}{{Tutorial/tool | }}{{Tutorial/tool | ||

|tool_name=Flathead screwdriver | |tool_name=Flathead screwdriver | ||

}}{{Tutorial/tool | }}{{Tutorial/tool | ||

|tool_name=Needlenose pliers | |tool_name=Needlenose pliers | ||

| Line 20: | Line 18: | ||

|errors={{Tutorial/error | |errors={{Tutorial/error | ||

|error_code=T19-XXX | |error_code=T19-XXX | ||

| | }}{{Tutorial/error | ||

|error_code=T19-207 | |||

}}{{Tutorial/error | |||

|error_code=T19-208 | |||

}}{{Tutorial/error | |||

|error_code=T19-216 | |||

}}{{Tutorial/error | |||

|error_code=T19 217 | |||

}} | }} | ||

}} | }} | ||

Revision as of 22:28, 29 January 2025

| Fix thermal-pressure motor lock | |

|---|---|

| Difficulty | Intermediate |

| Duration | 90 min. |

| For series | RZ, EZ, SF, MZ |

| Tools | |

| Parts | 612-10010 1 × TPH Gear |

| Error codes | T19-XXXT19-207T19-208T19-216T19 217 |

This tutorial[1] provides step-by-step instructions to replace a broken gear powered by the Thermal Pressure Motor. This process applies to most Riso Z-type (and beyond ) duplicators and is demonstrated here on an MZ1070. The error messages "T19-208" or similar codes such as "T19-XXX" may indicate the need for this replacement.

Overview

The gear in question is prone to wear over time. Replacement gears, such as part #612-10010, are commonly available on platforms like AliExpress or eBay. It is recommended to acquire the replacement part before beginning the procedure.

Steps

Configure

1: Remove the outer cover of the Master Removal Unit (feed side)

- Unscrew and remove the outer cover (5 screws in total). The left side may be slightly hooked.

2: Remove the top cover of the paper feed

- Unscrew and remove the plastic cover (2 screws). Pull the cover towards you and set it aside.

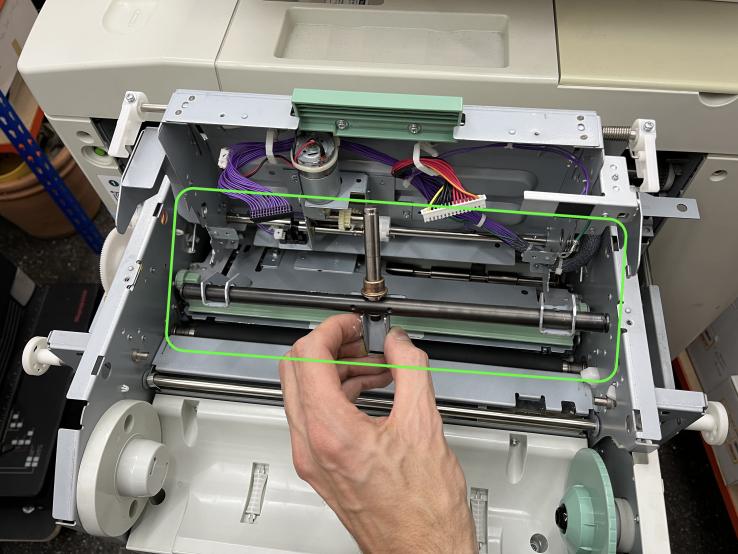

3: Disconnect cables and remove the Master Removal Unit

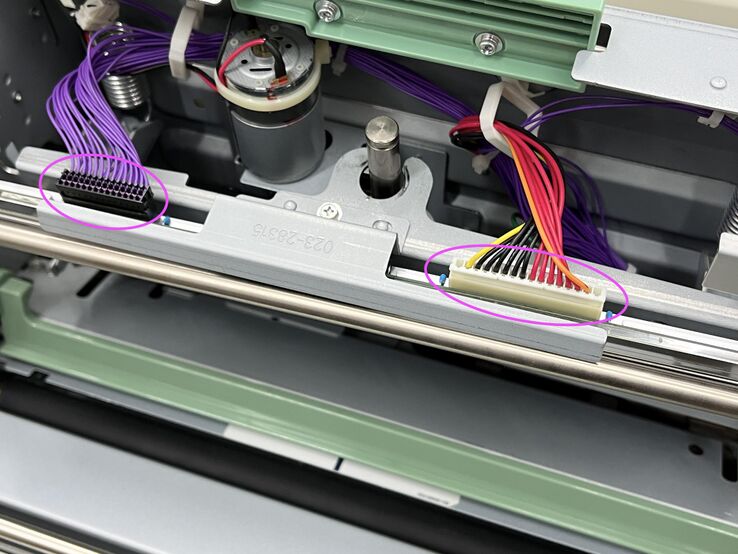

- Unplug 2 cables and the connector. Remove the cable clamp.

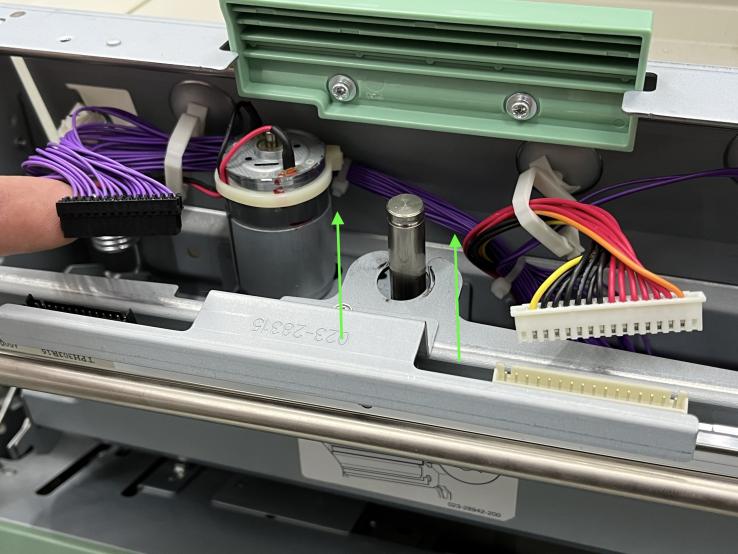

- Unscrew 2 screws holding the Master Removal Unit in place.

- Carefully pull the unit out; it is heavy.

4: Push the MMU towards the paper feed side

- Open the cover of the Master Making Unit (MMU) and push the MMU towards the opposite side. If it doesn’t move, proceed to the next step.

5: Press the plastic hook to advance the MMU

- Push the hook to allow the MMU to slide further into the machine.

6: Push the MMU all the way in

- Continue pushing the MMU until it stops.

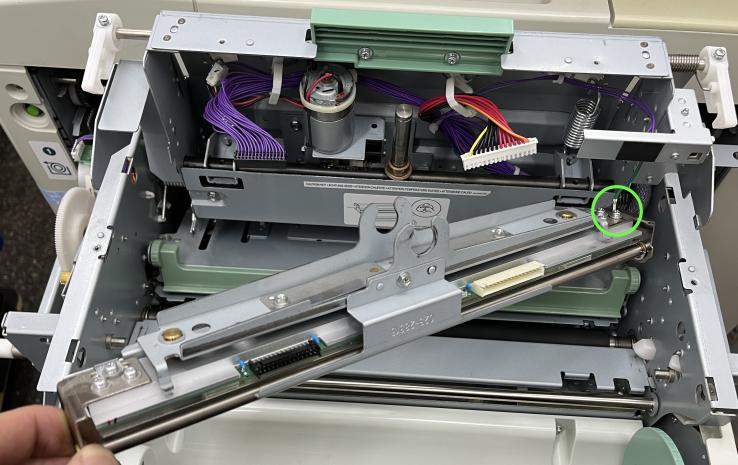

7: Remove screws from the Thermal Pressure Gear Cover

- From the paper feed side, unscrew 2 screws. Hold the MMU to prevent it from sliding back.

Open and disassemble the MMU

8: Remove the MMU bottom cover

- Unscrew 2 screws and set the cover aside.

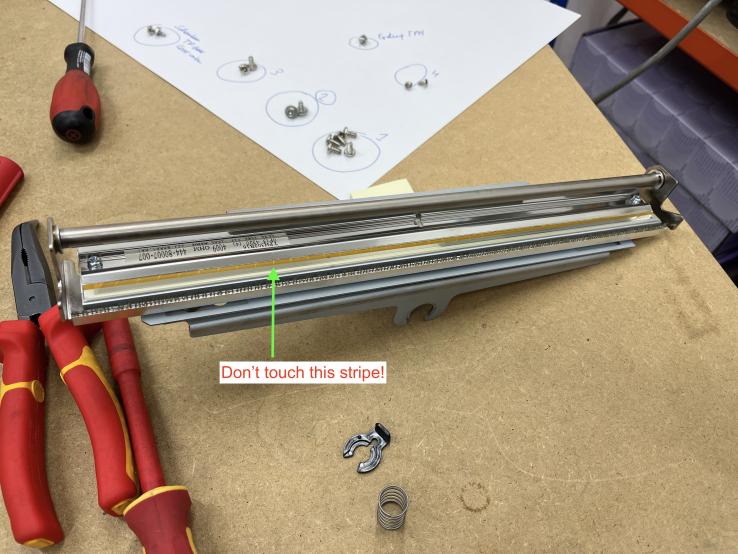

9: Remove the TPH

- Avoid touching the TPH stripe (yellow/orange color).

10: Lift and remove the top bronze bearing metal.

- Remove the black plastic snap ring and spring, and carefully remove the bronze bearing

11: Unplug 2 cables connected to the TPH

12: Carefully lift the TPH while holding the lower bronze bearing metal

- Before you can fully remove the TPH, you need to unscrew the grounding wire (see next step).

13: Unscrew the grounding wire

- Hold the TPH and unscrew the grounding screw (green, used with an eyelet to safely direct electricity to the ground) , ensuring it does not fall inside the MMU.

14: Set the TPH aside for now

- !!! Be careful to not touch the orange strip !!!

15: Remove the top screws of the Thermal Pressure Gear Cover

- Unscrew the top 2 screws to remove the cover.

Inspect and replace the gear

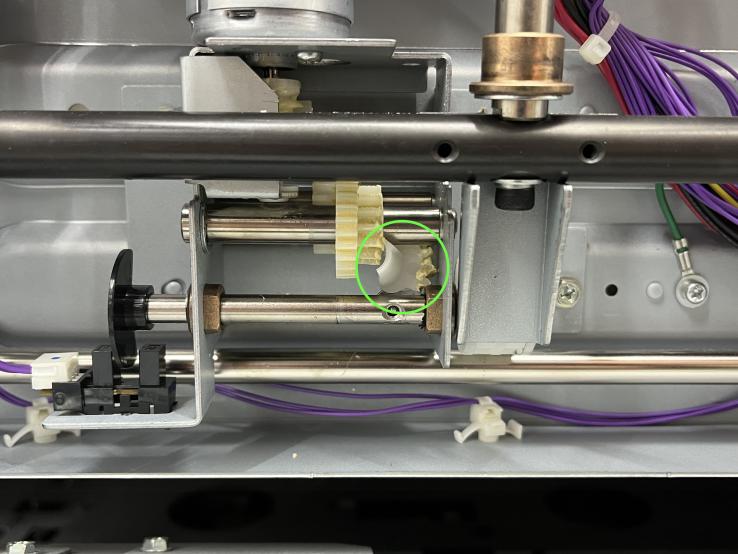

16: Check the gear

- Inspect the gear for damage. If it is intact, the issue may be elsewhere. It should be fairly obvious that the gear is broken, as you will likely find broken parts at the bottom of the enclosure.

- If the gear is not broken, you likely have a different issue.

17: Remove springs from the fulcrum shaft

- The fulcrum shaft is the black horizontal shaft. It needs to be removed to access the broken gear.

- Remove the springs with care, as they are under tension.

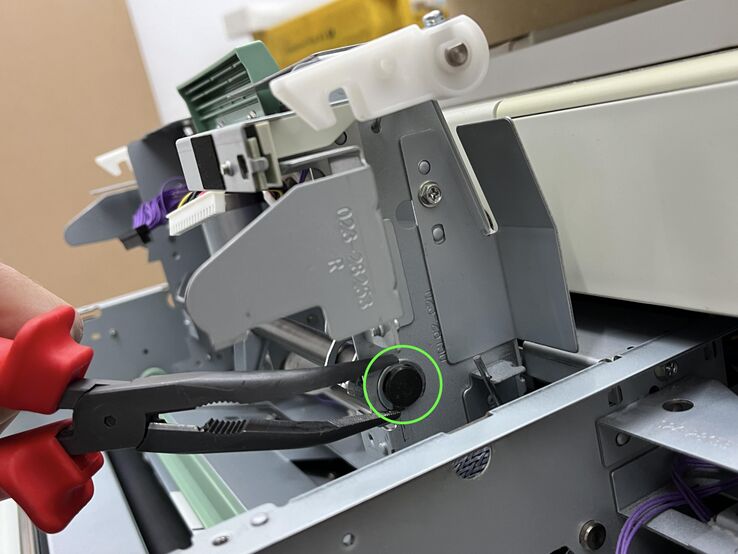

18: Remove e-rings from both sides of the fulcrum shaft

- Be careful: e-rings are tight and can jump off. Use special e-ring pliers or a screwdriver.

19: Remove the fulcrum shaft

- Extract the shaft to access the gear.

- Unscrew the white plastic piece and any remaining gear fragments. - Remove the tiny e-ring and push the shaft to the left.

21: Install the new gear

- Slide the new gear onto the shaft. - Reassemble the shaft and ensure the white plastic piece faces inward.

Put it back together

18: Reassemble =

- Grease the new gear and reassemble all components in reverse order.